Our Services

We provide comprehensive quality assurance and testing solutions for solar and storage projects. Our services span the entire lifecycle, from factory inspections and field diagnostics to laboratory investigations and system performance analysis. By combining deep technical expertise with transparent, actionable reporting, we help asset owners, EPCs, and investors de-risk projects, extend asset life, and maximize return on investment.

Our Services include:

- Field Testing & Diagnostics. - System Performance Analysis.

- Factory Inspections & Audits. - Warehouse & Security Oversight.

- Laboratory Investigations. - Independent Engineering & Equipment Expertise.

Read more below ↓

Field Testing & Diagnostics

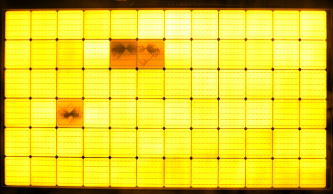

Electroluminescence (EL) Imaging

Day and night imaging that reveals microcracks, inactive cells, and connection faults within PV modules.

We bring advanced testing capabilities directly to the field to identify defects and performance issues before they impact return on investment.

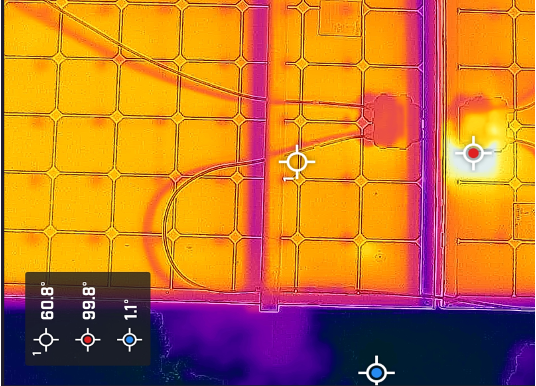

Infrared (IR) Thermography

Detects hotspots, thermal anomalies, and electrical imbalances that can indicate damage or degradation.

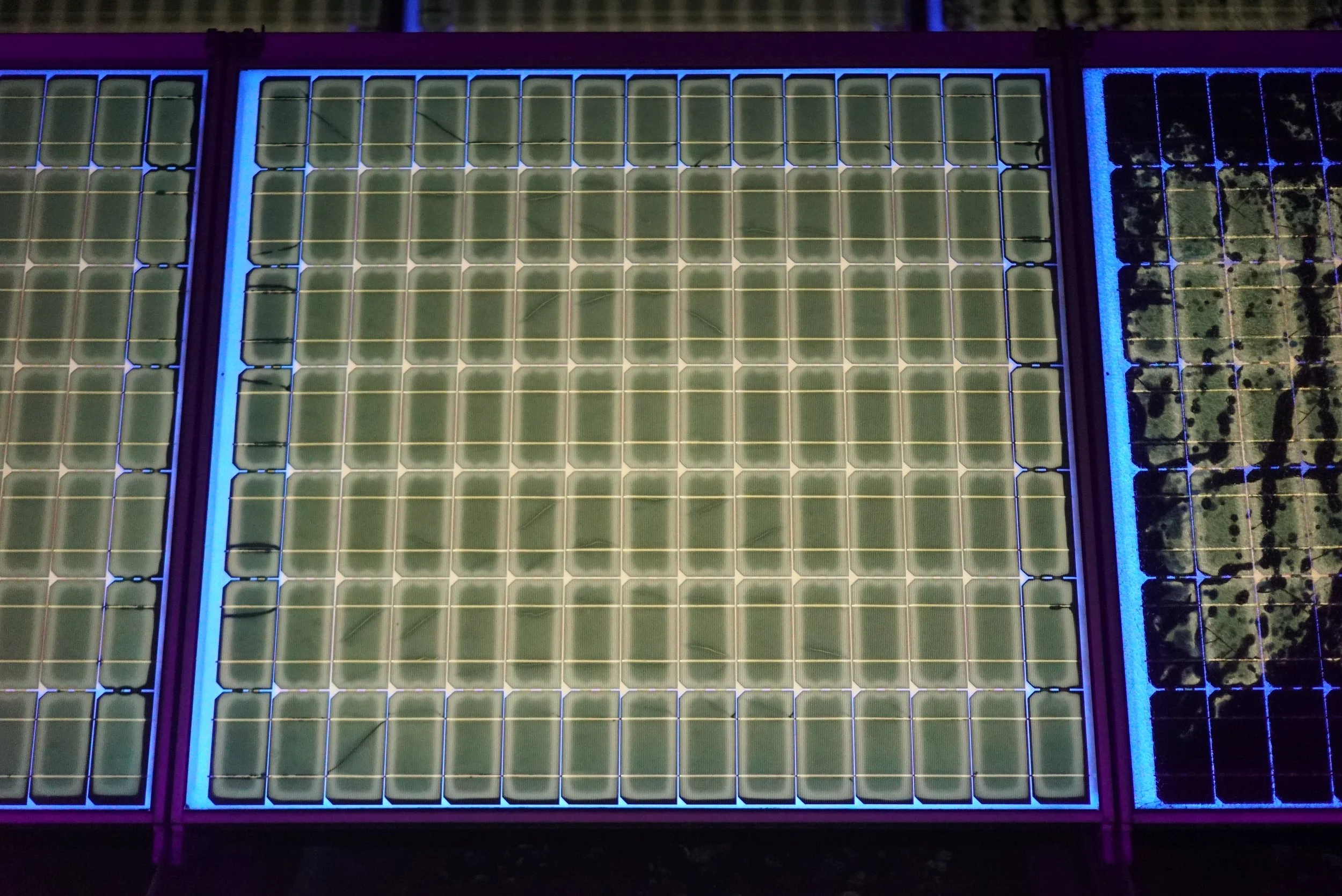

Ultraviolet Fluorescence (UVF) Testing

Identifies early signs of backsheet degradation, polymer breakdown, and other failures that affect reliability.

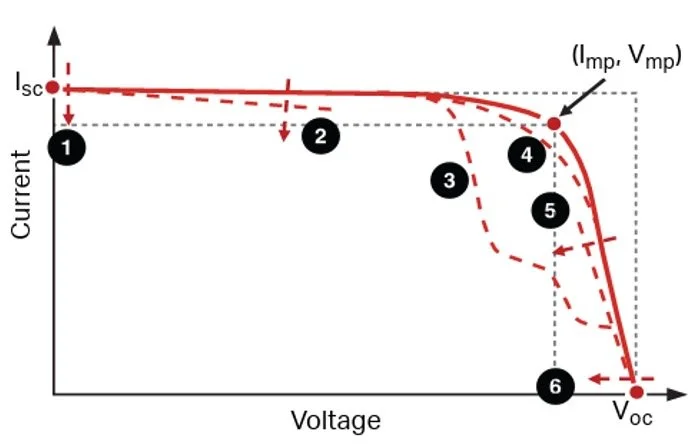

Current–Voltage (I-V) Curve Tracing

Measures and compares actual module or string performance against design specifications to verify system efficiency.

Factory Inspections & Audits

Our factory audits ensure that every component meets the highest quality standards before deployment, reducing the risk of performance issues in the field.

Bill of Materials (BOM) Verification and Production Supervision – Review and confirm component specifications, monitor manufacturing processes, and verify material traceability throughout production.

Witness Builds and Pre-Shipment Inspections (PSI) – Oversee product assembly, conduct on-site quality checks, and ensure that finished goods meet contractual and technical requirements prior to shipment.

Defect and Process Control Analysis – Identify manufacturing defects, evaluate process stability, and recommend corrective actions to maintain consistent product quality.

Container Loading Oversight – Supervise loading operations to ensure safe handling, accurate labeling, and proper documentation before transport.

Laboratory Investigations

When deeper analysis is needed, we collaborate with leading laboratories for comprehensive investigations.

Advanced Material Testing – Including Fourier Transform Infrared Spectroscopy (FTIR), X-Ray Diffraction (XRD), and Dark Current–Voltage (Dark I-V) measurements to evaluate material composition and electrical characteristics.

Reliability and Environmental Chamber Testing – Simulates long-term operating conditions to assess durability and predict product lifespan.

Moisture Ingress Detection and Hydro-Scanner Imaging – Identifies pathways for moisture penetration that can compromise module performance.

Root Cause Analysis – Detailed investigation of material and component failures to determine underlying causes and recommend corrective actions.

System Performance Analysis

We validate project performance against design and financial models to ensure long-term reliability and transparency.

Inverter and Module-Level Fault Diagnostics – Detailed testing and data analysis to identify electrical or performance issues within specific components or system sections.

Output Validation Against System Design – Compares actual energy production to design specifications and simulated performance models.

Return on Investment (ROI) and Financial Modeling – Evaluates project profitability by correlating real-world performance data with expected financial outcomes.

Weather–Performance Correlation Analysis – Compares system output to historical and real-time weather data to assess environmental impacts and performance consistency.

Warehouse & Security Oversight

We support safe, efficient, and secure component storage and handling to protect valuable solar equipment before installation.

Pallet Quality Control (QC) and Loading/Unloading Inspections – Examine pallets and packaging for damage, verify Bill of Lading (BOL) accuracy, and ensure safe handling during transport.

Inventory Tracking and Reconciliation – Maintain precise records of incoming and outgoing equipment to prevent loss and ensure traceability.

Forklift Safety and Facility Training – Provide operator training and on-site safety verification to reduce risks during warehouse operations.

Drone-Based Warehouse Mapping for Optimization – Use aerial imaging to evaluate storage layouts, identify inefficiencies, and improve space utilization.

Independent Engineering & Equipment Expertise

Our team brings decades of expertise in photovoltaic (PV) manufacturing, equipment quality, and regulatory compliance to support clients across the full project lifecycle.

Photovoltaic (PV) Equipment Consulting and Electrical Code Compliance – Provide expert guidance on PV system design, installation, and adherence to applicable electrical standards and safety codes.

Support for Return Merchandise Authorization (RMA) Claims and Warranty Documentation – Gather technical evidence and reporting to streamline manufacturer warranty and replacement processes.

Specialist Knowledge in PV Cell and Module Manufacturing – Offer deep insight into materials, processes, and product development to ensure long-term reliability and performance.